Ultrasonics or ultrasound, derived from the Latin words "ultra," meaning beyond, and "sonic," meaning sound, is a term used to describe sound waves that vibrate more rapidly than the human ear can detect.

Sound waves travel as concentric hollow spheres. The surfaces of the spheres are compressed air molecules, and the spaces between the spheres are expansions of the air molecules through which the sound waves travel. Sound waves are thus a series of compressions and expansions in the medium surrounding them. Although we are used to thinking of sound waves as traveling through air, they may also propagate through other media.

The technical name for one expansion and one compression is a cycle. Thus, a vibration rate of 50 cycles per second produces 50 expansions and 50 compressions each second. The term frequency designates the number of cycles per unit of time that a sound wave vibrates. One cycle per second is called a hertz and is abbreviated Hz. Other useful units of scale in ultrasonics are kilohertz (kHz), which represents 1,000 Hz; and megahertz (MHz), representing 1,000,000 Hz or 1,000 kHz.

Most people can only detect frequencies of sound that fall between 16 and 16,000 Hz. Ultrasonics has come to describe sound waves with frequencies greater than 16,000 Hz, or 16 kHz. Some insects can produce ultrasound with frequencies as high as 40 kHz. Small animals

such as cats and dogs hear frequencies of up to 30 kHz; and bats are known to detect frequencies of up to 100 kHz.

A sound wave that causes compressions and expansions of the molecules in the medium surrounding it as it propagates is called a longitudinal wave. The distance from one compression to the next is known as the wavelength of the sound wave. Sound waves with long wavelengths pass over small objects in much the same way that ocean waves pass over small objects. Sound waves with short wavelengths, on the other hand, tend to be diffracted or scattered by objects comparable to them in size.

The propagation velocity of a sound wave is obtained by multiplying the frequency of the sound wave by its wavelength. Thus, if the wavelength and frequency of the sound wave in a given medium are known, its velocity can also be calculated.

As ultrasonic waves tend to have very high frequencies, it follows that they also have very short wavelengths. As a result, ultrasonic waves can be focused in narrow, straight beams.

The number of applications for ultrasound seems to be limited only by the human imagination. There are literally dozens of ways that people have already found to make use of ultrasound.

Ultrasound has been used to bind, or coagulate, solid or liquid particles that are present in dust, mist, or smoke into larger clumps. The technique is used in a process called ultrasonic scrubbing, by which particulate matter is coagulated in smokestacks before it pollutes the atmosphere. Coagulation has also been used at airports to disperse fog and mist.

In ultrasonic humidification, water is reduced to a fine spray by means of ultrasonic vibrations. The water droplets are propelled into a chamber where they are mixed with air, and a mist of air and water leaves the humidifier and enters the room to be humidified.

Ultrasonic waves can be used to break up fat globules in milk, so that the fat mixes with the milk (homogenization). In addition, pasteurization, the removal of harmful bacteria and microorganisms, is sometimes done ultrasonically.

By attaching an ultrasonic impact grinder to a magnetostrictive transducer and using an abrasive liquid, holes of practically any shape can be drilled in hard, brittle materials such as tungsten carbide or precious stones. The actual cutting or drilling is done by feeding an abrasive material, frequently silicon carbide or aluminum oxide, to the cutting area.

In ultrasonic soldering, high frequency vibrations are used to produce microscopic bubbles in molten solder. This process removes the metal oxides from the joint or surface to be soldered, and eliminates the need for flux.

Conversations can be overheard without using microphones by directing ultrasonic waves at the window of the room being monitored. Sounds in the room cause the window to vibrate; the speech vibrations produce characteristic changes in the ultrasonic waves that are reflected back into the monitor. A transducer can be used to convert the reflected vibrations to electrical signals that can be reconstructed as audible sounds.

Radio talk shows routinely use ultrasonic delay lines to monitor and cut off abusive callers before their comments are aired during radio talk shows. The ultrasonic delay line bounces the voice signal back and forth between two transducers until it has been monitored, then releases it for broadcast.

Ultrasonics - Ultrasonic Dispersion

Two liquids that do not ordinarily mix, i.e., oil and water, can be combined as a liquid by exposing a solution of the two to very high frequency sound waves. Such mixtures are called dispersions. With this technique, alloys of aluminum and lead, iron and lead, and aluminum and cadmium can be mixed as liquids—and kept mixed—until they solidify. This technique is known as ultrasonic dispersion. It is also used to produce stable and consistent photographic emulsions.

Ultrasonics - Scientific Research

Ultrasound has been used to investigate the physical properties of materials, to determine the molecular weights of liquid polymers, to investigate the associated states of water, and to induce and speed up chemical reactions. Ultrasound has also been used to break up high molecular weight polymers, thereby making possible the creation of new plastic materials. Agricultural research indicates that seeds have been found to germinate more rapidly and to give higher yields after they have been subjected to ultrasound.

Ultrasonics - Medicine

Perhaps in no other field has there been such an explosion of ultrasound applications as in medicine. Ultrasound has been used in the following applications:

- to photograph body organs and bones. Body parts as small as 0.004 in (0.1 mm) may be imaged using ultrasound. Heart examinations may be performed to locate tumors, valve diseases, and accumulation of fluids. Pregnancies may be detected as early as five weeks after conception, and fetal size and development is monitored throughout pregnancy and delivery using ultrasonic imaging.

- to measure the rate and direction of blood flow using the principle that the frequency of sound changes as it travels toward an observer, but decreases as it moves away. This phenomenon, known as the Doppler effect, accounts for why the pitch of a train whistle, for example, becomes higher as a train first approaches, then becomes lower as it passes people standing on a station platform. Doctors can determine the direction of blood flow in the body by observing increases or decreases in the frequency of the ultrasonic measurements.

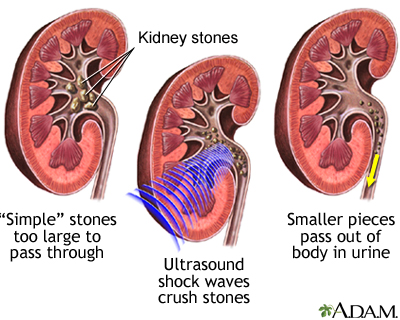

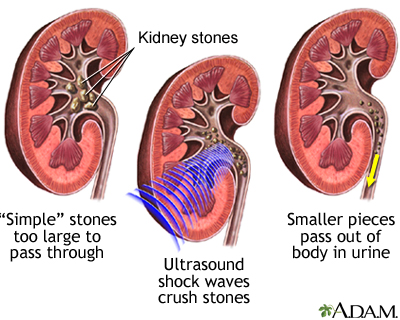

- to detect tumors in the body and to distinguish between malignant tumors and healthy tissue. Ultrasound is also employed by oncologists to destroy malignant tumors and inclusions, eliminating the need for surgery. Cancer cells are destroyed using ultrasound to produce microscopic bubbles that collapse and send out intense shock waves (cavitation effect). The same technique is used to destroy gallstones and kidney stones.

- to view living cells without damaging them. Ultrasonic microscopes can be used to image cellular structures to within 0.2 microns (two-thousandths of a millimeter). Ultrasonic methods are also used to locate foreign objects in the eye during surgery and in routine eye examinations, and to measure the depth of burns in burn patients. This technique affords an accuracy of 0.05-0.1 in (0.1-0.2 mm).

- to relieve muscle strain. Ultrasonic heat has been used to treat arthritis, bursitis, myelitis, neuralgia, malignancy, lumbago, rheumatism, arthritis, sciatica, sinitis, and post-operative pain.

- to clean teeth by means of ultrasonic prophylaxis units operating at 25 kHz.