Textile printing

Today's traditional textile and fashion market place is going through creative, technical and product development changes. Change is defined as verb meaning to make it different.

The five printing methods are distinguished by the method of image transfer and by the ordinary types of image bearer employed. Depending upon the process, the printed design is transferred to the substrate either directly nor indirectly. In direct printing, the image carrier to the material, example of direct printing are, flexography, screen printing and letterpress printing processes. In indirect or offset printing the image is transferred so quickly.

Textile printing is the process of applying color to fabric. In printing block and stencils plates, rollers, are used to place colors on the fabric. To prevent the color from spreading by capillary attraction beyond the limits of the pattern or design.

Some techniques were separately fashionable in 19th century, since were combination techniques in which indigo resist was used to make blue background prefer to block printing of other colors. Most modern industrialized printing uses direct printing techniques.

The general theory of printing

The printing of textile materials is the application of color according to a predetermined design.

The printing paste which is applied to textile material consists of dye, water, thickener and hydrocarbon solvent or oil. After the printing paste is applied the textile material is usually steamed. This is to enable the dye molecules to migrate from the surface of the fibers and to enter the fiber polymer system. Steaming swells the fibers and ensures better penetration of the dye and improved color fastness properties of the textile material.

The general theory of printing explains the interaction, on steaming, between the dye, fiber, water, thickener and hydrocarbon solvent. More specifically, it explains how within the printing paste:

1) Forces are repulsion are developed between the dye molecules and the constituents of the printing paste; and

2) Forces of attraction are developed between the dye molecules and the fibers of the textile material to be printed.

Textile orientation is an ancient art. It refers to the different processes by which fabrics are printed in colored design print fabric. Example of Greek fabrics from the 4th century B.C have been found. India exported block prints to the Mediterranean region in the 5th century B.C.

The invention of a dyed cotton fabric dating backward to the Indus Vally civilization demonstrates that the art of dyeing with the use of mordants was well known to the Indian dyers 5000 years ago. This form of dyeing was responsible for making India famous all over the world for its dyed and printed fabrics.

The dye molecule

The dye molecules are organic molecules which can be classified as:

1) Anionic - in which the color is caused by the anionic part of the dye molecule;

2) Cationic - in which the color is caused by the cationic part of the dye molecule;

3) Disperse - in which the color is caused by the whole molecule.

The first two molecule types are applied from an aqueous solution. This third is applied from an aqueous dispersion.

The role of the thickener

The purpose of the thickener is to produce a medium for the dye paste and resultant product is called the printing paste. The printing paste is an emulsion of thickener and hydrocarbon, such as white spirit or very light hydrocarbon oil, plus a surface active agent. This surface active agents enables the emulsification of the thickener with the hydrocarbon to form printing paste of uniform consistency. The uniform consistency of the printing paste is referred to as its viscosity. The viscosity of the printing paste is very important as it influences the clarity and appearance of the printed pattern. The success of printing textile materials depends very much on the type and quality of the thickener.

Thickeners can be any of the following:

1) Natural gums, such as gum arabic, acacia gums or gums prepared from starches and other polysaccharides;

2) The man-made, natural polymer-based gums, for example, water soluble cellulose ethers, such as carboxymethyl cellulose, methyl and ethyl cellulose, and sodium alginate; or

3) Occasionally, made-made, synthetic compounds such as polyvinyl alcohol.

Methods of textile printing

i) Hand printing

ii) Block printing

iii) Screen printing

iv) Spray printing

v) Kalamkari

vi) Batik

vii) Discharge printing

viii) Tie and dye

The trying of cloth with thread and then dyeing it is the simplest and perhaps on the plain piece of cloth. It is also the earliest forms of decorated textiles.

The fabric is washed. Often it is dipped in the mordant so that it can absorb the dye.The cloth is folded, first lengthwise then width wise into four fold. The patterns on the body are then indicated all over the surface with the use of blocks dipped in grue, a red mud color. The cloth is then printed with the left hand, one knots follow another, using the same thread.

Fabric Printing.

Fabric Dyeing is a color that is applied to a fabric in wet condition.The dyed fabric is also printed in special orders or for new fabric innovations in marketing.

Once the fabric is bleached it goes for printing and in some cases even a scoured and desized fabric goes to printing.

The prining of a fabric can be as good as possible by intelegent printing.There are several techniques in printing and there are several types of fabrics that needs several types of printing.A fabric that is used in fashion apperals for printing is in several ways different than a fabric that is printed for Head Gear.

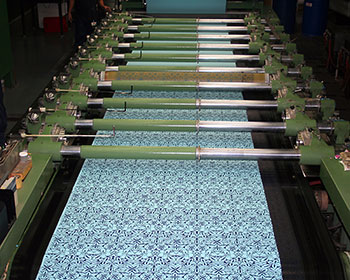

The picture that is given shows a fabric that is spread over a long table of several meters in length.The fabric is pasted evenly with a washable glue that is colorless and printed with made up screens as you see in the video for T Shirt printing but of a longer length and width.The process is same.However in case of Digital Prints as you can see in the video it is just like your PC Printer but huge in size and varies in design and work.

Once the fabric is printed it goes for wash and required finish.The finishing after wash is by the same machines as that which is used in finishing a dyed fabric.

Packing and marking is no different than other fabrics.The printed fabrics are not folded but rolled and sent to the market.

Textile Printing Designs

A printed fabric starts with a tightly woven flat base fabric made from any of a variety of yarns, including cotton, cotton blends, polyester, linen, silk, and other synthetics. The base fabric may or may non have woven designs. The printed design is applied to the fabric with pigment ink.

Printed fabric can be used in many applications: for clothing, upholstery, banners, umbrellas, tablecloths, ties, baby slings, handbags, and even surfboards. Some fabrics work better than others for certain applications.

Making printed fabric for upholstery or dressmaking is a traditional process. By applyingmodern technology to this age-old craft, printed fabric has risen to new heights of creativity. Digital printing, for example, has great promise as a custom printed fabric design technique because it is appropriate for small print jobs.

Direct printing is a type of digital printing in which pigment is applied directly to the fabric from a widebed printer. Digital fabric impression machines ar available for printing on any type of fabric with most any type of dye. The reward to digital impression is that there are no screen charges or minimums. For large runs, traditional impression is more cost effective but for short runs and one off patterns, digital impression is the answer for the up and coming designers and is a do-it-yourselfer’s dream. Digital impression also eliminates much of the waste from the dying and production processes. As a result, digital printing is a more eco-friendly kind of printing.

Interior designers and clothing designers contract with fabric impression companies to print their professionally created designer fabrics. Professional designers usually create the fabric designs using computer-assisted gimmick (CAD). These ar often large orders that ar used to make mass produced consumer items.

A recent increase in interest in crafts and do-it-yourself projects has led to a new industry of fabric impression for individual consumers. Designers don’t need any experience to create their own unique designer fabric. Here’s how custom fabric design works:

1. Find a vendor who does impression on fabric for small-scale projects.

2. If you are using your own design, provide the vendor with a scan or digital file of your image. You don’t’ need a design created by CAD to print your own fabric.

3. Choose the base fabric you want. Most online vendors will send swatches for free or for a small charge.

4. Decide how much fabric you need (one yard is usually the minimum) and find out from the vendor how much it will cost.

5. When the impression is complete, your custom fabric is ready for your project. That’s all there is to it!

Several new custom printing websites have competitions in which customers submit their designs for judgement by fellow customers. The companies may decide to use a winning design as a stock design, which is quite a tribute to the designer.

Custom printing opens new avenues of creativity. Online print companies make it easy to design personalized fabric and have it manufactured at reasonable cost.

Nice Digital Textile Printers in India blog and i will share to my friends. Also i suggest Textile Printing India.

ReplyDelete